The Challenges of

Third-Party Logistics

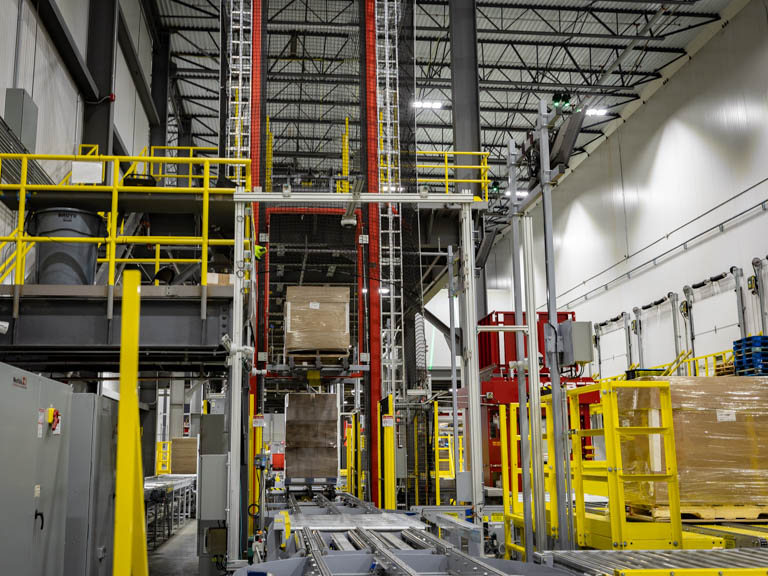

The 3PL industry faces unique challenges, including managing diverse client needs, handling a wide variety of SKUs, and ensuring quick turnaround times across multiple distribution channels. Westfalia understands these complexities and offers automated solutions designed to optimize your operations, improve service levels, and provide the flexibility needed to adapt to changing demands.

Why Automate Your 3PL Operations?

-

Scalability: Easily expand your operations to accommodate new clients and increased demand.

-

Cost Efficiency: Reduce labor costs and minimize errors through automated processes.

-

Improved Accuracy: Enhance order accuracy and inventory management with real-time tracking and automation.

-

Flexible Storage Solutions: Optimize space utilization with high-density storage and adaptable racking systems.

-

Pallet Versatility: Ensure reliable storage with our triple-rail support system, capable of handling any pallet type, regardless of condition—a critical advantage for 3PLs.

-

Client Satisfaction: Provide reliable, fast, and accurate service to your clients, ensuring their needs are met with precision and efficiency.

Automation for Every Third-Party Logistics Challenge

Our automated systems are built to meet the unique demands of third-party logistics providers. Whether you’re handling a wide variety of products, managing complex order fulfillment, or seeking to increase your storage capacity, our solutions are designed to enhance efficiency, reduce costs, and ensure smooth operations. From efficient pallet handling to precise inventory management, we have the tools you need to keep your 3PL business competitive.