Sargento Foods extended their distribution center’s lifespan by a decade with automation…

The food industry faces a unique set of challenges in warehousing and distribution. Managing perishable goods, maintaining stringent safety standards, and ensuring efficient operations require innovative solutions. We understand these challenges and offer automated systems designed to meet the specific needs of food companies. Our expertise ensures that your operations are efficient, compliant, and ready to meet the demands of a fast-paced market.

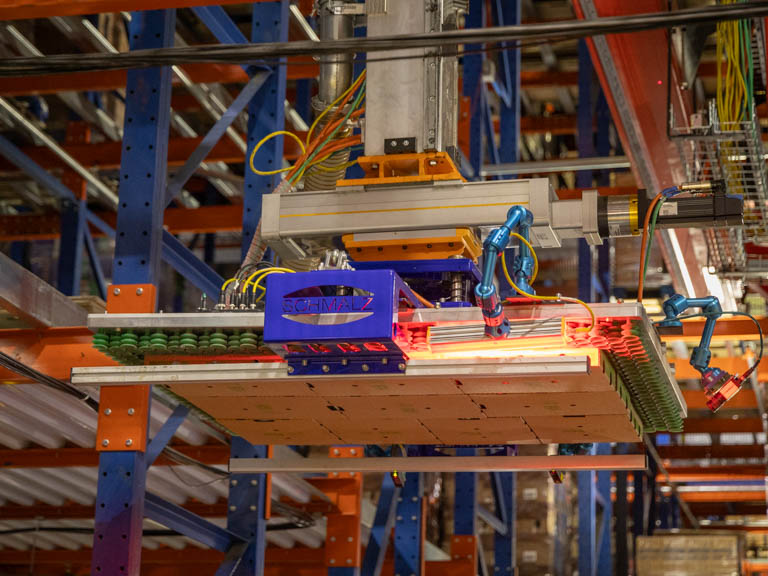

Westfalia offers a range of solutions tailored to the specific needs of the food industry. From cold storage and frozen goods to high-turnover items and complex distribution networks, our automated systems are designed to handle it all. We provide solutions that ensure your products are stored safely, tracked accurately, and delivered efficiently.