August 29 2013

Eliminate damage - automated warehousing systems for cold storage

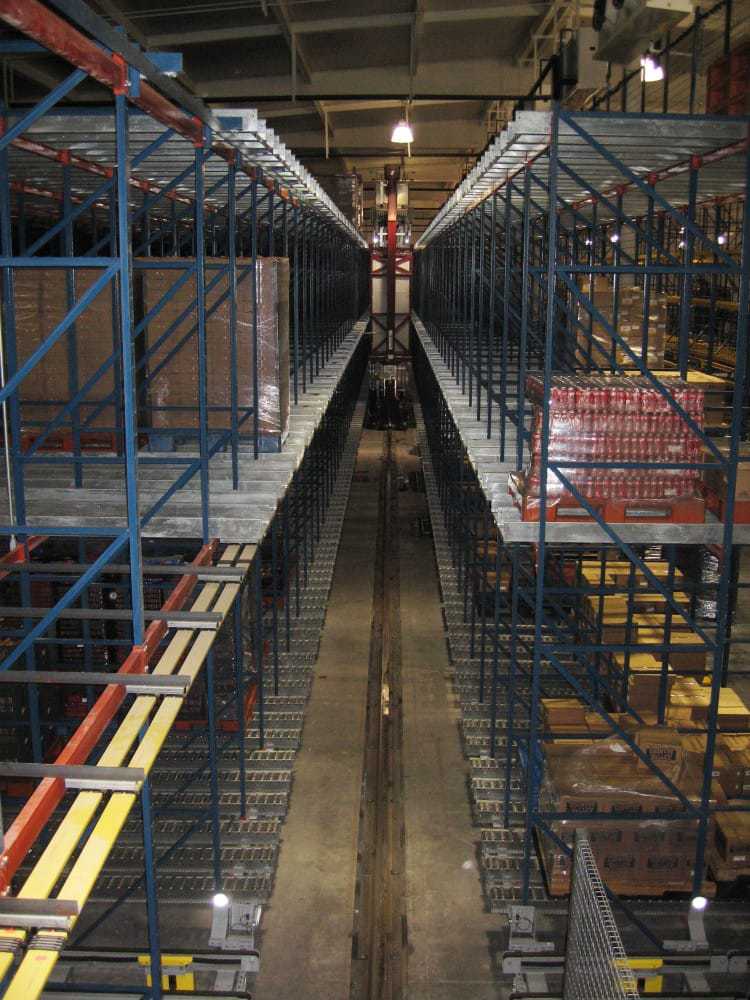

August 29, 2013 – York, Pa. --The human body wasn’t designed to work in sub-zero temperatures, yet the majority of frozen food and cold storage operations conduct warehousing activities completely manually with high personnel turnover in these types of facilities due to the chilly temperatures. These manual operations pose operational and logistical challenges such as increased product, facility and equipment damage, labor turnover, and errors in order fulfillment. These types of challenges can easily be eliminated with an Automated Storage and Retrieval System (AS/RS).

Westfalia Technologies Inc. specializes in high-density AS/RS for cooler and freezer facilities. In fact, most manufacturing operations that store frozen products are candidates for high-density storage because typically a small number of items account for 80 percent or more of the volume and inventory.

Westfalia’s AS/RS’s are primarily used to store and buffer materials safely. They can store raw materials to service a production process, Work-in-Process (WIP) to buffer materials during the manufacturing process, and finished goods to allow longer and more efficient production runs, and meet immediate customer demands.

Common components include:

- Storage/Retrieval Machine(s) (S/RM’s)

- Satellite® or Telescopic Fork load extraction devices

- Savanna.NET® Warehouse Management System (WMS)

- Triple rail support to protect the pallet during storage

- Integration with other warehousing and logistical systems such as pick-to-light, truck routing software, print-and-apply devices, stretch-wrappers/palletizers, and all common types of conveying systems.

There really are no building size requirements for Westfalia’s AS/RS’s. Installations are common in regular industrial buildings, with ceiling heights of 20 feet to 35 feet, as well as 130-foot tall rack supported structures. Westfalia’s high-density systems allow cooler and freezer facilities to store unit loads two to 18 pallets deep, while reducing the 12-foot-wide aisles of a typical cold storage facility. AS/RS also provides discrete access to each lane on every level, improving utilization levels over drive-in or floor storage layouts. With the smallest system deployed handling about 500 pallet rack positions, Westfalia has also installed AS/RS’s storing over 60,000 positions. A typical Storage/Retrieval Machine is capable of handling (storing/retrieving) between 60 and 120 unit loads per hour depending on whether one or two loads are moved at the same time.

AS/RS’s are playing a broader role in cold storage, decreasing the operational and logistical challenges many face in these environments. A well-designed system integrates the reserve storage and re-supply of product to some type of order selection process, whether automated, semi-automated, or manual.