February 22 2016

Driving Just-in-Time Order Fulfillment with a Warehouse Execution System

According to the American Transportation Association (ATA), there could be a 175,000 truck driver shortage by 2024. A shortage of this this size will affect many industries, as well as force warehouses to rethink their order fulfillment strategy.

How does the trucking crisis impact warehousing operations? In an article written by Westfalia’s Dave Williams, director of software and solutions delivery, he reviews how the lack of drivers means delayed pickups resulting in staged orders sitting and taking up valuable space. Williams also offers suggestions on how to combat this problem by implementing just-in-time (JIT) order fulfillment strategies with an automated storage and retrieval systems (AS/RS)

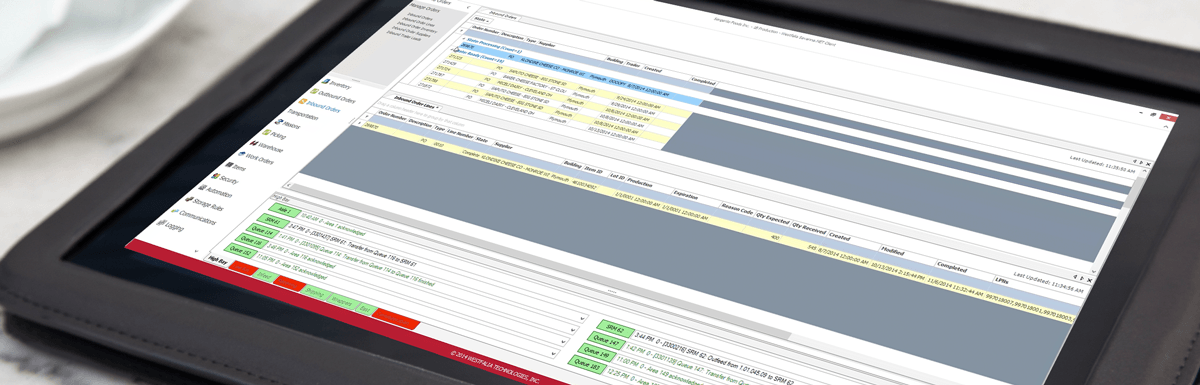

In order to achieve the most efficient warehouse, he recommends implementing a warehouse execution system (WES) as the software that runs the AS/RS. This software solution combines the functionality of a WMS and a WCS into one application and can direct the entire warehouse from start to finish. Williams explains the following benefits of using a WES for JIT order fulfillment:

- Quickly and easily retrieve product right when it is needed

- Allows operators to prioritize and manage orders

- Ensures product accuracy and quality

- Performs pre-shipment activities

- Can be efficient in a non-automated or slightly modified facility

By implementing a WES with JIT order fulfillment, warehouse operators will be prepared for whatever may happen with the trucking industry in the future.

To read the full article published by Supply & Demand Chain Executive click here