January 11 2013

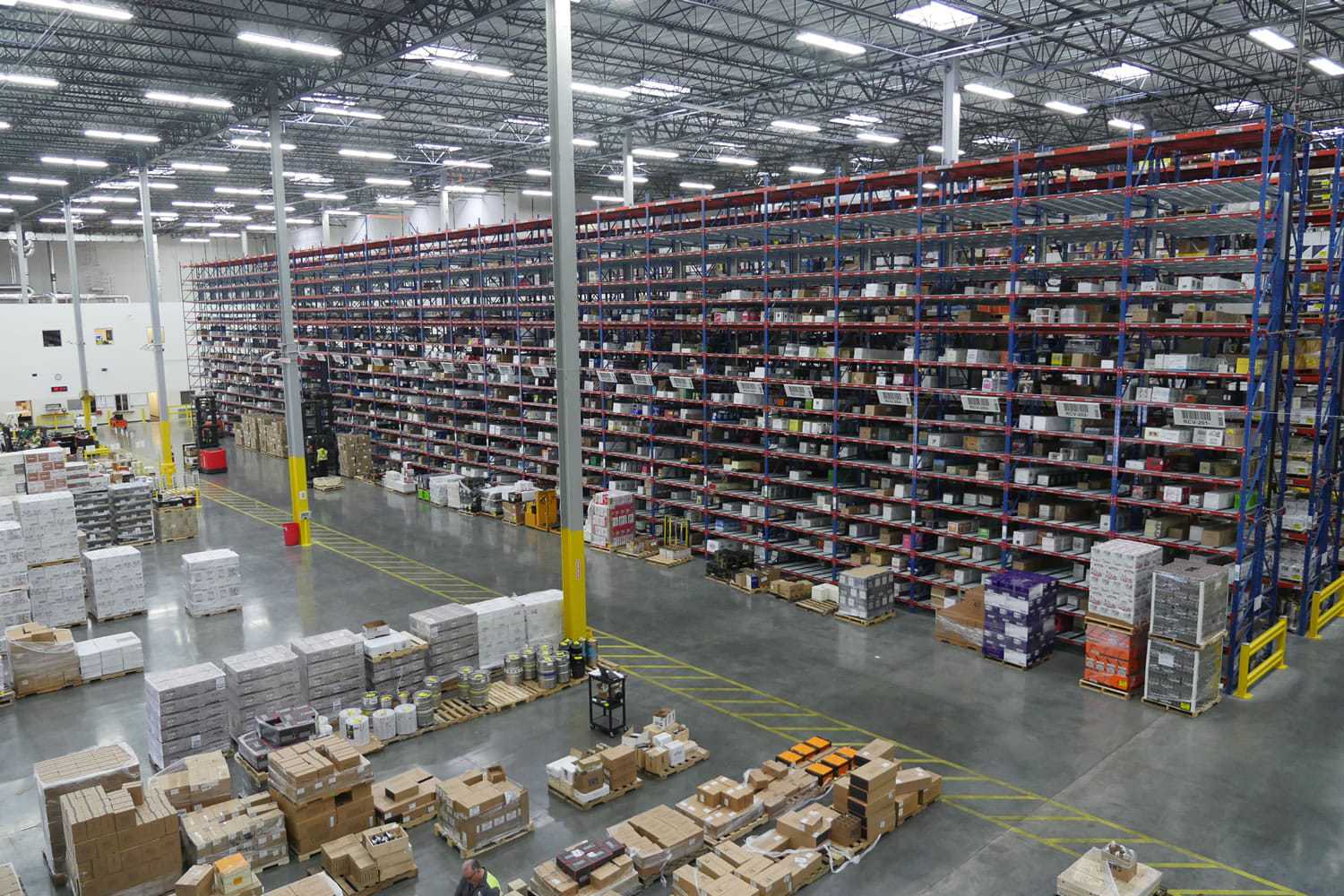

AS/RS's aren't Only for High Rise Warehouses

AS/RS’s are feasible and economical in existing low bay warehouses

YORK, Pa., January 1, 2013 – Westfalia Technologies installs Automated Storage and Retrieval Systems (AS/RS) in warehouses only 20’ high. A common misperception of AS/RS is that they are only for new, high-rise buildings, when in fact AS/RS’s are feasible and economical in existing low bay warehouses.

With high density systems offering pallet storage three, four, or even up to 12 deep, these systems offer much greater storage density. Depending on the pallet load dimension (weight & height), often another level or more of rack can be added in an existing facility—even if it’s only 20’ high.

As Dan Labell, President of Westfalia Technologies, Inc. explains, “While our competitors focus on storing products only one, two or three deep, we have the technology to go from one to 12 deep. Depending on the SKU mix of fast, medium and slow movers, a high density low bay automated warehouse system is feasible. It really comes down to the SKU mix.”

The key is their Satellite® rack entry vehicle which smoothly and quickly glides under the pallet, gently lifts it, and moves it back to the crane (S/RM). The rack structure has no moving parts, making the system more reliable and maintenance less costly. Westfalia can perform a quick inventory analysis to determine the best lane depth for a facility. High moving items (or SKUs) can be stored in longer storage lanes, thereby enabling a high density storage solution. Each facility’s mix of fast, medium and slow moving items determines the viability of AS/RS in any low bay or high rise warehouse.